"Making tomorrow's yesterday today."

pipe organs, packet radio, time-sharing computer systems, and advanced lawnmower technology

This website contains information on the construction of an electric action pipe organ by an amateur organbuilder. This organ is to have a novel wind system with electronically governed pressure. The instrument is intended to not only showcase this new technology but also to be liturgically useful and good for the playing of suitable literature. This is not a high-art organ project, but rather the "digital hillbilly" approach to organ construction. The purpose of this site is to no only record the progress of the project, but also to serve as my own reference for specifications and designs, so it will necessarily contain granular implementation details for the whole instrument.

I have been interested in the construction of organs for almost as long as my interest in organs themselves. Organ technology was irresistable to me from the day I asked my father how the organ at church got its wind, being enamored of fans and blowers since early childhood. If asked (nobody ever does), I can trace the origins of Opus 1 to a sketch made in Mr. Gerka's 6th grade Social Studies class. To me in middle school, anything worth making could be constructed from foamboard and hot glue, my cheif medium at the time. Years later, I would eventually succeed in making speaking pipes (of quite good timbre I must boast) of foamboard construction.

I would go on to make several doomed attempts at starting to build Opus 1. While it would be poetic to have a single reason for my past attempts falling apart, it was a culmination of insufficient reasearch, scarcity of materials and capital, and general naïveté in approach. However, over these years I have managed to accumulate enough pipework, chests, magnets, wind system parts, and solid state gadgets to have a more reasonable starting point. As for the research, a great deal more has been done. As for the naïveté, may God have mercy.

Presently, the main audience of the website is non-organbuilders, which is the reason for my taking the time to treat words and ideas that are familiar or obvious to organbuilders. The pedantic tone should subside after the necessary vocabulary and background are introduced for each topic. This taking time to define and explain helps me to reify my own understanding of organbuilding ideas. No doubt, more credentialed readers will find some of my exposition faulty or, at the most generous, 'oversimplified'. My treatment of the history of some organbuilding trends will be hyperbolic and lacking subtlety to the point of crassness.

Unless specified, all discussion is about pipe organs. The casual reader should understand that if I call an organ 'electric', I'm not referring to how it produces sound but rather how the pallets (valves) are made to move.

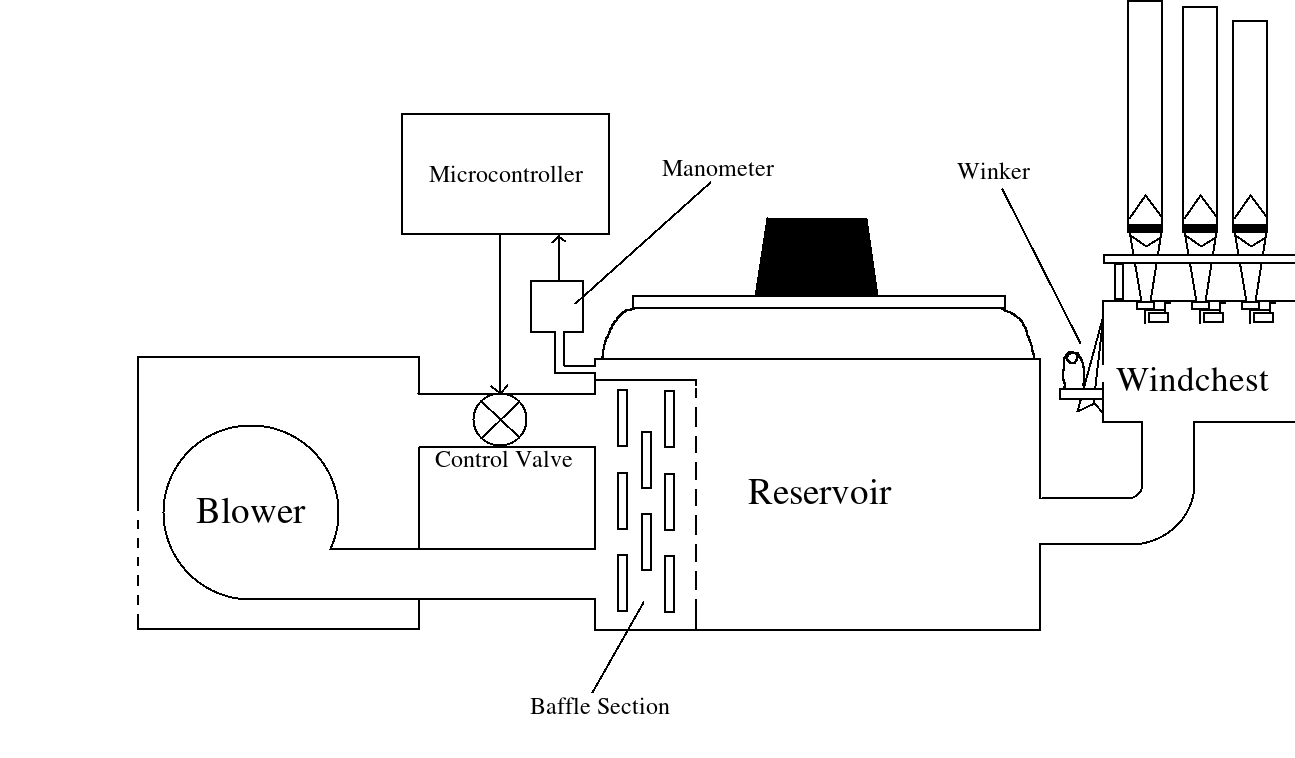

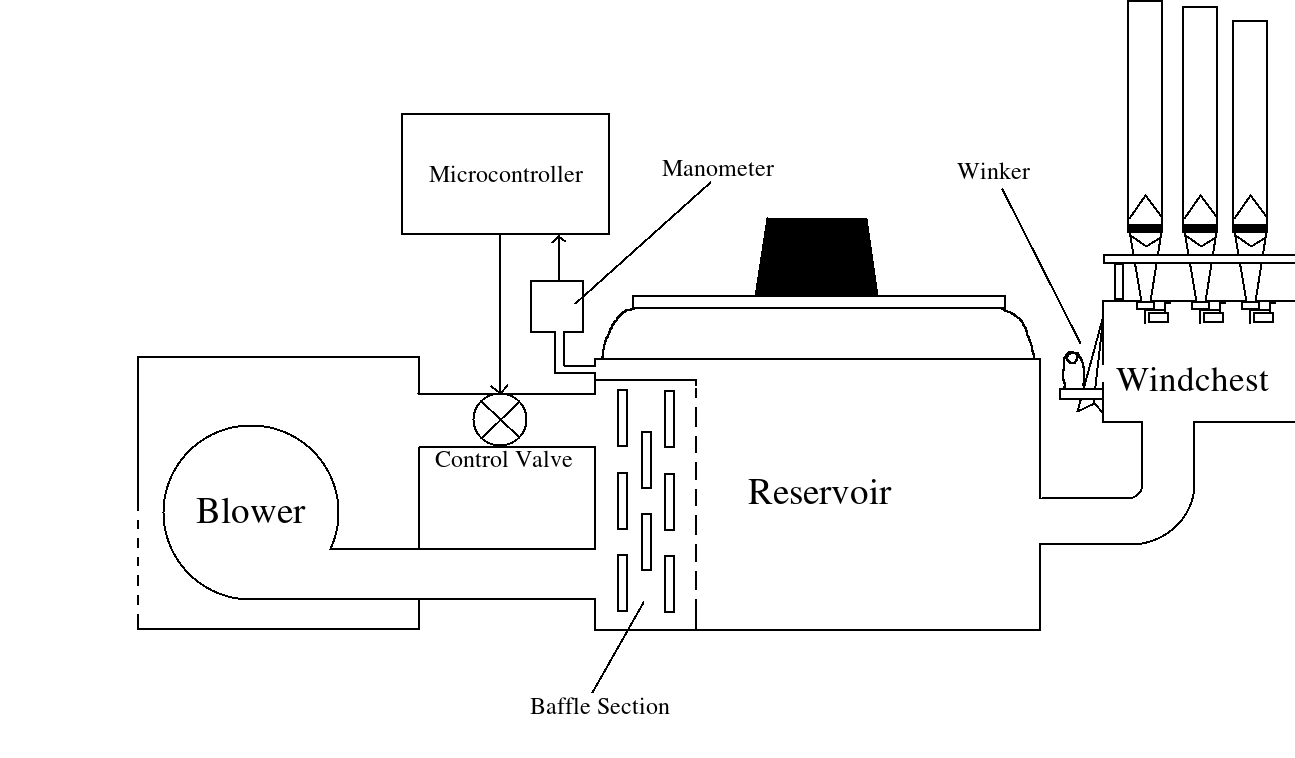

I am working on a post about the wind system design of Opus 1. It

will go here. For now, have a look at the diagram I made in KDE

Kolourpaint.

To give the possibility of meaningful discussion with my colleagues outside the organ wheelhouse, I must get you all up to speed on the latest in organ wind technology. Let's start in Ancient Greece.

It happened that springtime brought organbuilding season this year. Rather than messing around with chests, pipes, and reservoirs my return to the project this time is in the electronics lab. In some earlier writings (limited publication, leet hackers only) I gave an argument as to why the wind system was a good place to start. It is still true that the wind system must be among the earliest functioning parts of the organ and I shall be getting back to mine in short order. My wind system design, being electronically governed, also has a good deal of electronics work; but the part of the organ that is entirely electronics work is the action (until the wind is on and adds complications).

The last time I was working on the project, I got a pizeo pressure sensor wired up to a microcontroller and began to take some test readings. The sensor was tee'd with a conventional U-tube manometer for calibration. Then I got an ADC with more bits, for want of windpressure measurements at a higher resolution. If a wind fluctuation is great enough to be preceived in the speech of the upperwork, I want the computer to be aware of it. The research component of my previous organbuilding spell was significant. Let me tell you that good information on organ wind systems is extremely scarce on the Web. The problem is that the overlap between those with detailed knowlege on organ wind systems and those who publish prolifically on Web is very small. Some more organ wind theory could be enjoyed from print publications -- maybe I should buy some. I stopped short at getting in contact with an organbuilder, something which I have done in the past for questions much lesser. When I recommence the construction of the wind system, I will write an organbuilder at the first sign of trouble; hopefully though, my error-tolerant design will get me far.

So here we come back to the organ project, and we are building an action. Maybe you can blame this on the fact that I was recently asked to play an Easter service -- I was interacting with a 1969 E.H. Holloway as its player, and that made me wonder how it would be to play Opus 1. I think it's reasonable to say an organist's first impression of an instrument is heavily informed by its console or keydesk. The renewed sense of the importance of my organ study made me consider that the machinery that facilitates the actual playing of the organ was just as important as the sound-producting machinery. After all, were it not for the monks refining the keyboards and actions of church organs around the beginning of the 2nd millennium, today's virtuosic keyboard music would not be possible.

What is an organ console? It's where the organ's input devices are! The console only became commonplace in 'modern' organbuilding, requiring precise and well-regulated mechanical, pneumatic, or electrical systems for its separation from the organ itself. The old, traditional construction of a pipe organ is for the organist to be seated at the case of the instrument, with the manuals (hand keyboards), pedalboard, stop jambs, and music desk made into the side. This is called a keydesk. With the advancement in sacred choral literature, a separate console with line-of-sight to singers or a conductor came to be of great utility in liturgy. Having a separate console also allowed for more flexibility in installation: the organist could sit with the choir and the pipe chambers or organ case could be whereever (for better or for worse).

Here is a mechanical action organ having a traditional attached keydesk. It's Dobson's Opus 35, a Italian baroque studio organ with a big American pedalboard. Top floor of the round building. I've played a few secondary organ student juries on it. Don't worry, I didn't use any heels in my Bach.

What is an action? All organs have to have one. 'Action' is the word for the machinery that connects the movement of the keys and pedals to the valves under the pipes. Before the industrial revolution, all pipe organs had a mechanical action, meaning that the keys and pedals had a hard physical linkage to the pallet valves in the windchest, accomplished with compositions of simple machines in the form of backfalls, squares, stickers, rollers, and trackers. Pneumatic actions used bundles of pencil-diameter lead tubes to tranmit what I might call pneumatic "control impulses" to cause the opening of pallets or movement of sliders. This allowed considerable flexibility in console detachment but long tubing runs caused sluggish responses. The problem of detached (and even movable) organ consoles was licked for good when electrified actions became practical. While the 'business end' at the chest may very, but electric actions have contacts at keys, whereby completing a circuit they can activate a chest magnet through either an old-fashioned relay or a multiplexed transmission.

The advent of organ electrification did not instantly solve all ills! (It introduced many yet unheard of!) Prior to the famous Robert Hope-Jones, who would invent the theater organ (a heavy user of electric gadgetry), a few brave experimenters in continental Europe and perhaps America attempted organ action electrification with varied results. Early electric actions used rapidly-draining wet batteries and crudely-constructed, hot-running solenoids. Amperages were large, and arcing and carbon buildup on the key contacts was common. With the advancement of electromechanical technology and the doings of genius/shyster weirdos like Hope-Jones, eventually, electrified actions became practical and accepted in mainstream organbuilding (for better or for worse).

Any discussion on organ actions would be lacking if it did not compare the experiences of playing a traditional mechanical action organ to playing an organ with electrified or even *disgruntled noises* tubular pneumatic action. A mechanical action organ is a touch-sensitive instrument, but not in the same way a pianoforte is. The cheif innovation of the piano was in making a keyboard with great dynamic expression -- this is because the actual kinetic energy that excites the string into vibration comes in one stroke, from the finger of the pianist, so the dynamic and timbre is necessarily proportional to the key-striking. An effect of being a percussive chorophone is that the note begins to decay immediately after being struck as no more energy is being imparted to the string after its initial sounding. Playing the organ is very different because the pipe will continue to sound with unchanging dynamic and timbre until the key is released. The touch sensitivity of a mechanical action organ can therefore not be during the sustaining of a note, but rather at note transients: attack and release (but the attack moreso perhaps). Like how the hardness of a piano hammer-strike can be modulated by the key-press, the movement of an organ windchest pallet is directly coupled to the movement of the key, giving the organist the ability, with sensitive technique, to control the note transient phases. We will get to the those clickin' and tickin' Wicks'es and the series-of-tubes soon, I promise.

In present day organ pedagogy, after shaking off the neobaroque fever dream of the Orgelbewegung, well-regulated mechanical action organs are now considered the gold standard for teaching and playing the literature. Personally, I have played more mechanical action organs than electric ones which is unusual because I reckon electric action organs greatly outnumber mechanical action organs in the present day United States. My institutional organ pedagogy was almost entirely on mechanical action organs, taking place in a building with one of the greatest concentrations of such instruments in the world. This comes off as braggadocious, because mechanical action organs are coveted, but it's simply the fashion in organ pedagogy and perhaps for good reason. Very excellent organists can take full advantage of the expressiveness afforded by mechanical actions, but it takes an extremely disciplined technique. Mechanical action organs are also excellent for pedagogy because they are extremely honest: an organ with a light and sensitive action (as is usually desired) will readily highlight any grazing of adjacent keys and pedals, or make obvious any lack of discipline in technique! Preferences in organ actions among elite performers of Baroque literature have turned to suspended mechanical actions, where the key is literally hanging from the pallet in the windchest.

Surely I have convinced you that every pipe organ worth a damn must have a mechanical action to be truly musical and expressive! Well, for one thing, not all mechanical action organs are well-regulated and musically-expressive instruments. (Astute organologists will notice that I have not yet called an organ 'a tracker', but merely referred to the component.) For all the greif that Europeans give Americans over the bizarre things we've done to pipe organs, they have their own history of bungling and hacking. (Hacking does not have a positive connotation in the organ world at it does for those who know computer history.) In the romantic period, tonal preferences and in-vogue construction techniques gave rise to many instruments with heavy, ponderous, and unresponsive actions. Many of these actions were probably defective on the drafting board and should have never been built. In fact, until the recent popular revival of historic organ construction techniques and designs, it was far more likely that "mechanical action" could evoke a negative connotation for organists.

You see, in the Romantic era, in response to fashions, liturgical trends, and changes in the writing and tastes of composers, windpressures were increasing to facilitate the production of the buttery and round tonal colors that were in vogue. The control of attack transients and clarity of voices in ensemble, which was later identified in the Orgelbewegung to be the essence of baroque organ sound, gave way to affect-dripping orchestral washes of tone with sometimes kaleidoscopically changing stop registration. A symphonic organ, like those built by Cavaille-Coll, necessarily has lots of voices, high windpressures, and pipes demanding great volumes of wind. The pallets are huge, and the force of the wind acting on them, along with the long and complex action, causes the keys to be very difficult to press! So much for the for your organ teacher telling you to play "like you're petting a cat", some organs it seems you have to beat the shit out of to get anything to articulate. If only we could all have fingers like Daniel Roth. All this aforementioned musicality of touch-sensitivity was lost on the heavy Romantic organ. Some organbuilders it seems lost the knowledge of building sensitive actions, and European and American perpitrators built heavy or otherwise defective and unmusical mechanical action organs well into the 20th century. But this need to overcome heavy actions in the Romantic era gave rise to great innovations, so it was not ultimately a return to the organs of the first millenium, where the keys were as big as batons on a carillon and had to be beaten down against a zephyr raised by twenty peasants stomping on forty sack-bellows.

One innovation used by the aforementioned Cavaille-Coll was a piece of pneumatic machinery called a Barker lever, which relayed the key action by means of pneumatic motor, acting in series with a mechanical action. Mr. Barker may not have been the very first to build such a contrivance, but he was successful in marketing it. Today, the very excellent organ firm C.B. Fisk makes a modern version of this called a 'servopneumatic lever', invented by Mr. Kowalyshyn. This is like a Barker machine but makes the pallet movement more in proportion to the keypress, instead of being a boolean. Cavaille-Coll not only made extensive use of the Barker machine but also was an early adopter of tubular-pneumatic actions.

We have talked so far about mechanical action organs and how they can be the gold standard, unplayable mechanical clusterfucks, or anywhere in between. We have talked about how penumatic machinery can be placed in series with a mechanical action to amplify the force of the keypress and about pneumatic 'relay signals' in tubes. Tubular-pneumatic organs were seldom built after the 1950's, save by some holdouts with large factories tooled for it.... [rewriting this paragraph now]

The late senator Ted Stevens inspects an Internet backbone router.

The late senator Ted Stevens inspects an Internet backbone router.

When abused (and it was), a tubular pneumatic action can cause a troublesome propagation delay in the keypress, as a charge or rarefaction of pressure travels down the small lead tubes. If the run is short enough to mitigate the propagation delay, the organ will be playable, but otherwise the results get comments like this:

"[Tubular-pneumatic action is] a complete failure; you cannot play a triplet on the Trumpet, and I consider it the most damnable invention ever placed inside an organ."

As I suggested earlier, first-generation electrified organs were crude in implementation until Hope-Jones developed an exceedingly practical action magnet which became widely imitated. This gave rise to what we now call the electro-pneumatic action where the magnet does not operate the pallet directly but rather actuates a pneumatic motor which opens the pallet. The pneumatic motor is often two stages. The operation is very interesting and I'm tempted to explain it here, but it's not in the scope of this post. The kind of action for the first chests I will construct will not be electro-pneumatic, but it will be electric. Direct electric.

Anybody who has heard of 'direct electic' organ actions has heard of the Wicks company, which made this action famous and infamous. Wicks has always occupied the 'entry level' part of the pipe organ market for those more in demand of utility than high art. This is not to suggest that all their installations are substandard, many are excellent. However, like many developing technologies it wasn't memorable for times when it blended in and 'just worked', instead, everything that was different or exaggerated from contemporary organ actions made the caricature of the clicking, ticking, coughing, spitting, sizzling, sparking Wicks.

Copyright (c) 2023, Big Chungus Research Systems

Copying and redistribution of this website are permitted provided this notice is preserved.

This website was made in GNU Emacs!